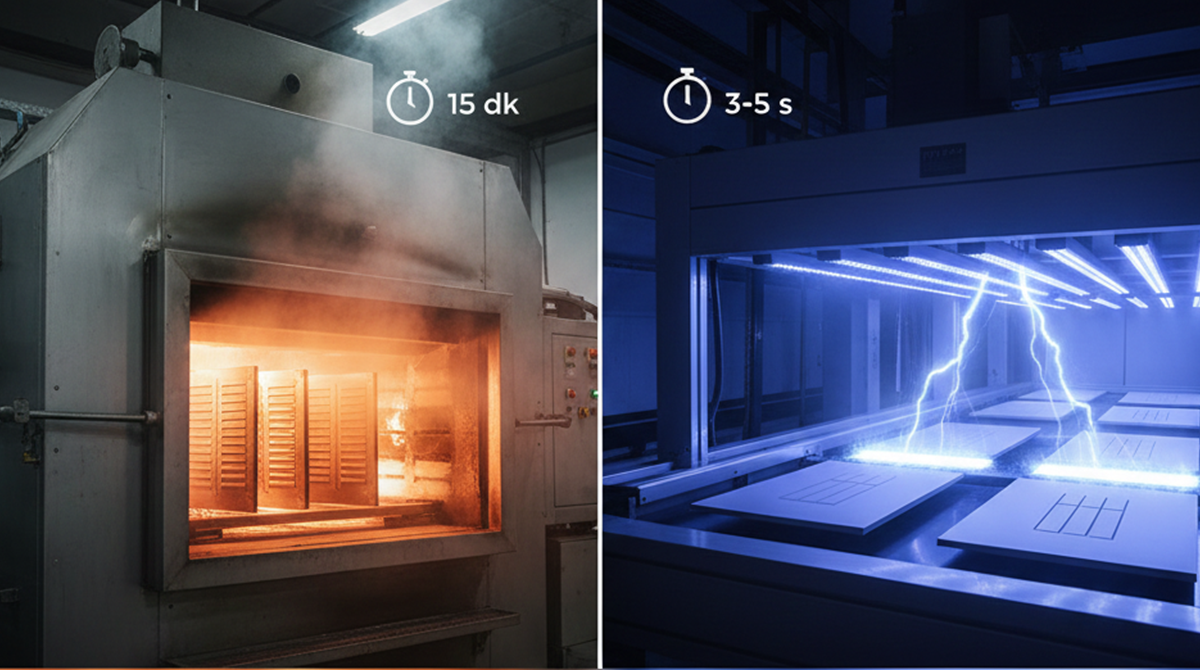

Each panel/part waits an average of 15 minutes in the drying oven on your production line. For a monthly production of 10,000 units, this means 150,000 minutes = 2,500 hours = 104 days of drying time. If your line operates 16 hours/day, 62% of this time is spent waiting for drying.

This figure is the average value for wood coating, plastic coating and printing facilities using thermal drying. UV curing systems reduce this time to 3-5 seconds. Production speed can theoretically increase 180-300x – in practice, the actual increase is around 3-5x due to bottlenecks. But that’s not what changes the ROI calculation.

- Oven power: 120-180 kW

- Operating time: 16 hours/day

- Daily consumption: ~2,400 kWh

- Electricity cost (@3 TL/kWh): 7,200 TL/day

- Annual (300 working days): 2,160,000 TL

- Varnish/coating consumption: 30 liters/day

- Solvent content: 30-40% (evaporating portion)

- Solvent loss: 9-12 liters/day

- Cost: ~1,200 TL/day

- Annual: 360,000 TL

- Drying oven: 1,500,000-2,500,000 TL

- Ventilation system: 400,000-600,000 TL

- Total CAPEX: ~2,000,000 TL

- 10-year depreciation: 200,000 TL/year

- UV LED modül gücü: 12-18 kW

- Çalışma süresi: 16 saat/gün (ama instant on/off, gerçek çalışma %30-40)

- Günlük tüketim: ~100 kWh

- Elektrik maliyeti: 300 TL/gün

- Yıllık: 90,000 TL

- UV coating consumption: 28 liters/day (100% solid content, no loss)

- Solvent loss: 0 TL

- UV coating price premium: +15-25%

- Annual: ~420,000 TL (premium included)

- UV LED system: 2,500,000-4,000,000 TL

- No ventilation required

- Total CAPEX: ~3,000,000 TL

- 10-year depreciation: 300,000 TL/year

Photopolymerization Reaction

In thermal drying, molecular motion is accelerated by heat and the solvent evaporates. This is a physical process – chemical change is minimal. In UV curing:

- UV photons (λ = 365-405 nm) excite photoinitiator molecules

- Photoinitiator decomposes to form free radicals/cations

- Free radicals trigger oligomer and monomer chains

- Polymerization (cross-linking) occurs

- In 3-5 seconds, a solid, 3D network polymer forms

This is a chemical reaction – energy is only needed to initiate the reaction, the continuation is exothermic.

- Spectrum: 200-600 nm (broadband)

- Power density: 80-240 W/cm

- Lifetime: 800-2,000 hours

- Instant on/off: No (warm-up 2-5 minutes)

- Heat generation: High (IR radiation)

- Cost: Low CAPEX, high OPEX

- Spectrum: 365, 385, 395, 405 nm (narrowband, selectable)

- Power density: 5-15 W/cm (but targeted emission)

- Lifetime: 20,000-50,000 hours

- Instant on/off: Yes (milliseconds)

- Heat generation: Minimal

- Cost: High CAPEX, low OPEX

| Application | Process Parameters | Technical Challenges | Solution | Work Output |

|---|---|---|---|---|

| Wood and MDF Coatings |

|

|

|

|

| Plastic Part Coating (Automotive, Electronics) |

|

|

|

|

| Flexo/Offset Printing (Packaging, Labels) |

|

|

|

|

| Adhesive and Bonding Applications |

|

|

|

|