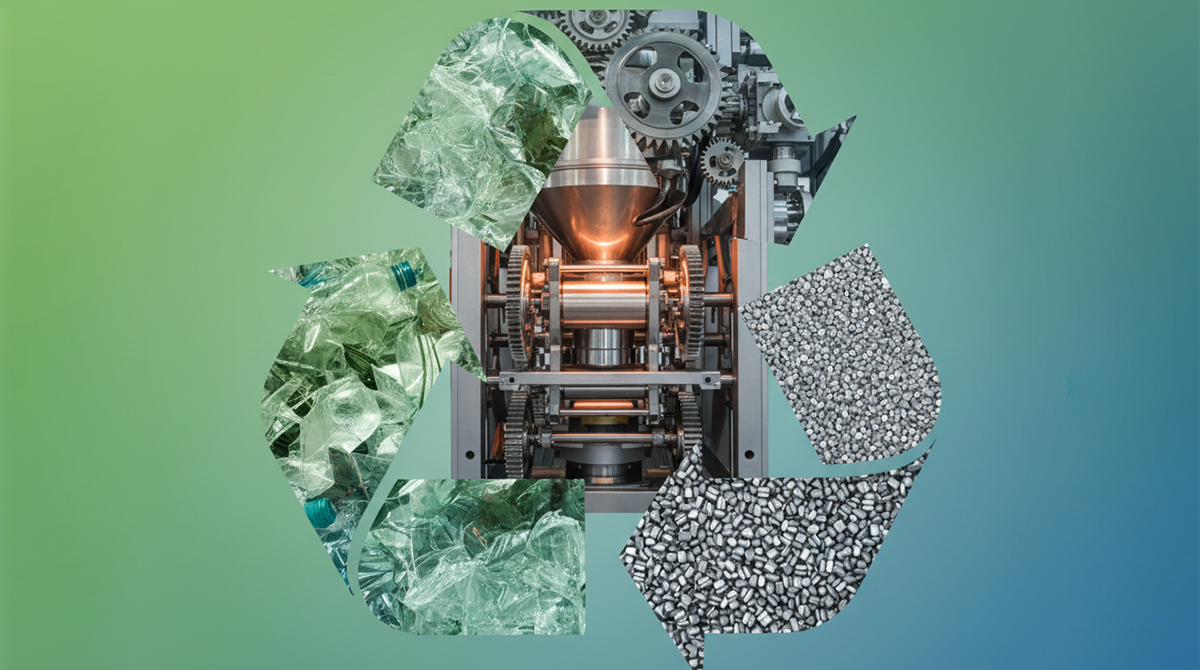

“The quality difference between virgin material and recycled material has now almost disappeared. Thanks to modern extrusion technologies, recycled granules obtained from in-house scraps show the same performance as virgin material.”

— Tim Pohl, Sustainability Expert, Reifenhäuser Group

Factory manager Mr. Mehmet faces the same scene every morning: piles of scrap plastic accumulating next to the extrusion line. Every month, tons of valuable material go to waste, raw material costs are constantly increasing, and competitors are getting ahead in the market with sustainability certificates. “Setting up a recycling system is too complex and expensive,” he thinks. But is it really?

More than 70% of plastic packaging and film manufacturers in Turkey still do not effectively recycle in-house scrap plastics. However, with the right technology, the same scraps can be returned to the production line at nearly 100%. This is not just an environmental issue – it’s also a serious cost advantage.

In 2020, Turkey’s municipal waste recycling rate was 12.3%, ranking third from last among 36 European countries. In the European Union, this rate is 49.6%. However, the picture becomes interesting right here: Turkish manufacturers have the technical capacity to compete with global players in in-house plastic recycling, they just need the right equipment and approach.

The story of Istanbul-based flexible packaging manufacturer Sürmeli Plastik perfectly exemplifies this potential. After establishing a recycling system in 2024, they now use scrap plastics—previously used for pallet and trash bin production—as raw material in high-quality packaging film production. The result? An annual 18% raw material savings and return on investment within 6 months.

There are three critical technological developments behind this change:

1. New Generation Twin-Screw Extruders

While traditional single-screw extruders struggle to handle recycled materials, co-rotating twin-screw systems have changed the rules of the game. These systems:

- Homogenize heterogeneous recycled materials: Scrap plastics of different qualities and viscosities can be processed in a single system

- Provide high throughput with low energy consumption: Up to 30% energy savings compared to classic systems

- Direct fluff (film particle) processing capability: Completely eliminates the energy-intensive regranulation step

Reifenhäuser’s EVO Fusion technology is a perfect example of this. At the Bioflex facility in Mexico, low-quality post-industrial scrap that could previously only be used in pallet and plastic container production is now being used in high-performance polyethylene film production.

2. Degassing and Contaminant Removal Systems

The biggest problem in recycled materials is contamination – moisture, volatiles, foreign particles. Multi-stage vacuum degassing units in modern extrusion lines have radically solved this problem:

- Pre-volatile removal under atmospheric pressure

- Main degassing under deep vacuum (0.1-1 mbar)

- Particle cleaning with inline filtration systems

The result? The possibility of using recycled material even in FDA-approved food-contact products. With Reifenhäuser’s PET sheet technology, it is now possible to produce food-safe meat trays from 100% PET bottle fragments.

3. Smart Process Control Systems

The biggest challenge with recycled materials: Properties that vary from batch to batch. While the scrap received one day shows 2.5 MFI, the next day it can be 4.2 MFI. In the traditional production approach, this causes hours of adjustment changes and tons of scrap.

ExtrusionOS and similar AI-supported control systems solve this problem:

- Real-time viscosity adaptation: Screw speed, temperature profile and feed rate are automatically optimized

- Predictive maintenance: Replacement time for wear parts is calculated in advance

- OEE (Overall Equipment Effectiveness) monitoring: Production efficiency is continuously maximized

The economic justification for in-house plastic recycling is stronger than ever in today’s market conditions:

Raw Material Cost Reality (Q4 2024 prices):

- • Virgin LDPE: ~38-42 TL/kg

- • Virgin LLDPE: ~40-44 TL/kg

- • Virgin PP: ~36-40 TL/kg

- • In-house recycled granule: 0 TL/kg (processing cost only)

For a medium-sized film extruder (50 tons monthly production, 15% scrap rate), the calculation is simple:

Annual scrap amount: 50 tons x 12 months x 0.15 = 90 tons

Without recycling system:

- • Scrap sales revenue (low-quality recyclate): 90 tons x 15 TL/kg = 1,350,000 TL

- • Virgin material purchase: 90 tons x 40 TL/kg = 3,600,000 TL

- • Net loss: 2,250,000 TL/year

With recycling system:

- • System investment (compact line): ~2,500,000-3,500,000 TL

- • Operating cost: ~5 TL/kg (energy, labor, maintenance)

- • Savings: 90 tons x (40 TL – 5 TL) = 3,150,000 TL/year

- • Investment payback period: 10-13 months

Challenge 1: The Perception That “Recycling Reduces Quality”

Reality: It was a justified concern in the 1990s, completely wrong in 2024. In modern inline recycling systems, scrap plastic returns directly to the production line without ever going outside and without being contaminated.

Solution: Controlled recycled material injection with side-feeder system. First layer virgin, middle layer recycled, final layer virgin again. 30-40% recycling rate, zero quality loss in the final product.

Challenge 2: High Initial Investment Cost

Reality: A fully integrated system is indeed expensive. However, it is possible to start with a modular approach.

Solution: Step-by-step investment:

- Phase 1 (3-6 months): Shredder + simple single-screw granulator = 800,000-1,200,000 TL

- Phase 2 (6-12 months): Side-feeder integration = 400,000-600,000 TL

- Phase 3 (12-24 months): Twin-screw upgrade + filtration = 1,500,000-2,000,000 TL

Each phase provides positive ROI on its own.

Challenge 3: Lack of Technical Knowledge

Reality: Your extrusion operators are already experienced in screw profile, temperature and speed optimization. Processing recycled material is expanding existing knowledge – not learning from scratch.

Solution: Comprehensive machine supplier support. Reifenhäuser, CMS and other European manufacturers offer active technical support in Turkey. First 2-4 weeks of commissioning and operator training included.

The European Union’s Packaging and Packaging Waste Regulation (PPWR) directive mandates a minimum of 30% recycled content in plastic packaging by 2030. For manufacturers exporting to Turkey, this will become mandatory, not optional.

More importantly, major brands’ sustainability demands are increasing. Global companies like Unilever, P&G, Nestlé are requesting carbon footprint reporting from their suppliers. In-house recycling systems are the fastest and most economical way to meet these demands.

Let’s return to Mr. Mehmet’s story. He can continue looking at piles of scrap plastic, saying “it’s too complex.” Or he can watch his competitors produce at 20% lower costs 12 months from now, as his customers shift to seeking sustainable suppliers.

The alternative? Take action today. Evaluate your current extrusion line’s recycling compatibility, analyze your material flow, make a modular investment plan. Many manufacturers in Turkey are already on this path – and the results are very clear: Lower costs, higher competitiveness, more sustainable future.

The recycling revolution in the plastic extrusion industry has begun.

The question is: Do you want to be a pioneer of this revolution, or one of those left behind?